CRL Report: Jewett Mine Cars Project

Reconstructing Historic Mine Cars

Nautical Archaeology Program, Texas A&M University

Pit Car No. 2 following construction

Introduction

Between 1998 and 2001, the strip mining operations conducted by Northwestern Resources Company at the old Jewett Mine unearthed the remains of several pit cars dating to the early twentieth century. These remains were brought to the Conservation Research Laboratory at Texas A&M University in order to reconstruct the pit cars for display. Because none of the cars was complete and the various components were damaged, the goal was to incorporate the different elements into the reconstruction of three complete cars. The conservation work has been undertaken by Mark Feulner and Troy Nowak under the supervision of Donny L. Hamilton.

Background

In 1907, the Houston County Coal and Manufacturing Company opened Mine Number 1 in northwestern Leon County, Texas. A small town called Evansville was established nearby as a community for the miners. The mines at Evansville were underground shafts. Entry was down a vertical shaft using a device called a tipple that was used to raise and lower the cages that carried men, mules and coal cars into the mine. The mining operation was a simple process: lignite was removed by the miners, either by hand or by powder blasting, then loaded into the 1½ ton pit cars. The loaded cars were hauled by mules to the shaft, where they were raised in the cages. At the surface, the car was dumped and the lignite was sent down a chute to a railcar for shipping. In 24 years of operation, about 1,200,000 tons of lignite were extracted at Evansville using this method. The last shaft at Evansville closed in 1931, when mining lignite became unprofitable. The community was abandoned as the inhabitants moved on to other jobs. Strip mining replaced the type of operation used at Evansville, providing a safer and more economical means of extracting coal.

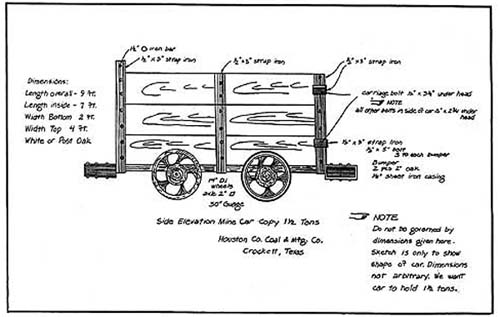

Drawing of a pit car used at the Evansville and Beargrass mines

(from Espey, Huston and Associates 1983: Figure 28).

Construction

Eagle Iron Works originally manufactured the pit cars used at Evansville, and they provided the Conservation Research Laboratory with plans for three early designs. In general, the cars consisted of three heavy bottom planks resting on two iron axles. The two outer planks tapered at the ends. A piece of iron was bolted over the ends, enclosing a wooden chock on the underside of the taper; these formed the “bumpers”. The central timber was shorter, and carried a longitudinal strap along its length. This strap was looped at either end to receive the hook or chain assembly for linking cars or harnessing mules.

Pit Car No. 2 following conservation

The three bottom planks were held by three transverse iron straps bolted to their undersides. These were bent upward to frame the sides of the car. Each side consisted of a narrow plank bolted to the straps as they rose vertically from the bottom. The straps then bent out over the wheels at a 45° angle, where another narrow plank was mounted. The straps then returned to a vertical run, with a wide plank, a narrow one and a very wide plank bolted to them to complete the side.

The rear of the car consisted of two vertical iron straps bolted to the outside of the bottom planks, to which the end planks were attached. The front of the pit car was where the coal was dumped, and therefore was moveable; the two vertical straps that held the end planks were not bolted to the bottom planks, but instead to two pairs of iron straps that extended back to the central transverse strap on either side. Each pair of straps was welded together to form a V and loosely bolted to the top of the central iron strap on each side of the car, forming the hinges. An iron handle was mounted on the top of the end plank for lifting.

Two different methods were used to mount the wheels. The earlier cars had two square axles secured by two iron straps that passed over them and the central transverse strap on the outer planks. The ends of the axles were rounded to receive the cast iron wheels, which featured oil wheels to keep the axle lubricated. The later pit cars used a more sophisticated wheel assembly. The axles were cylindrical, and were not directly secured to the car. They passed through four wheel-boxes that were held in position on either side with thin iron straps. The boxes were bolted to the underside of the bottom planks. Each box received one cast iron wheel, which was held in place by a pair of iron bolts dropped vertically into either side of the box. The wheel had a groove that would allow it to be retained by the bolts without its rotation being restricted. Inside the wheel were nine cylindrical steel bearings held in a frame. The axle passed through this entire assembly.

Treatment

Iron Conservation

In the case of Pit Car No. 1, the axles, wheels and axle straps underwent electrolytic cleaning. The straps and axles were made of wrought iron and appeared to benefit from this treatment. However, the original cast iron wheels were badly corroded; they deteriorated badly during electrolysis and some surface material was lost. Due to the superior condition of the wheel assemblies available from another coal car, these were used in their place.

Because the iron components did not have significant levels of chlorides that needed to be removed, electrolytic treatment was deemed unnecessary. Instead, mechanical cleaning to remove dirt and oxidation was adopted. This included the use of both an air abrasive tool (air scribe) and sand blasting. Once cleaned, the iron components were coated with tannic acid to prevent further corrosion. A final layer of polyurethane was used to seal the iron.

Interior view of Pit Car No. 2 following conservation

Wood Conservation

The wood components were thoroughly cleaned and treated with microcrystalline wax. Care was taken to avoid distortion of the planks.

Reconstruction

Pit Car No. 1 was reconstructed using components (planks, straps and wheel assembly) from at least three different cars; however, every effort was made to avoid the use of modern materials in the reconstruction. Pit Car No. 2 was largely intact when recovered and all components, aside from fastenings, are original. The original fastenings could not be used for reconstruction as they were badly corroded. Modern bolts were used in their place.

Current work

Two incomplete pit cars were received at the Conservation Research Laboratory during the fall of 2001. These pieces were conserved and reconstructed into a single pit car by Nautical Archaeology Program student Troy J. Nowak during the spring of 2002 and are now on display in the lobby of Northwestern Mining Resources, Inc. in Jewett, Texas.

Citation Information:

Mark A. Feulner and Troy J. Nowak

2002, Reconstructing Historic Mine Cars, Conservation Research Laboratory Research Report #13, World Wide Web, URL, https://liberalarts.tamu.edu/nautarch/crl/jewett-mine-cars-project/, Nautical Archaeology Program, Texas A&M University.