A chest from the Brother Jonathan shipwreck – part 2

California State Lands Commission / Institute for Western Maritime Archaeology

Following a three-month hiatus due to summer fieldwork, excavation and conservation of the crate from the Brother Jonathan shipwreck resumed in August 2001. Conservation began on artifacts removed in spring 2001, and new artifacts were uncovered as the excavation of the crate continued. Prior to removal from the crate, each artifact was fully documented, including photographs and scale drawings on a site plan. After extraction from the concretion and prior to conservation, each artifact underwent further documentation and analysis.

The first set of axe handles (BJ-17-5) after cleaning.

Axe Handles

The six axe handles removed in spring 2001 (BJ-17-5) were stored in water over the summer. Encrustation and graphite from the axe heads were cleaned from the handles. Desalination required two baths of rainwater and three baths of deionized water. Dehydration of the first set of handles will be completed by the end of summer 2002 and conservation will begin in fall 2002. Due to the excellent state of preservation, the acetone-rosin method will be used to conserve wooden artifacts removed from the crate. The wood cells are impregnated with pine rosin, imparting a golden color to the wood and yielding a strong, stable artifact.

The second set of axe handles (BJ-17-6) was successfully removed as a complete package during spring 2002. As with the earlier set, the heads were wrapped in paper. It is hoped that some identification data, perhaps in the form of imprinted maker’s marks will be discernible on the preserved paper.

Wooden hatchet handle with silicone rubber cast of iron head.

Hatchets

Two packages, each containing six hatchets, were found stacked on top of each other. Due its inherent fragility, the paper used to wrap the heads has disintegrated. Within the wrapping paper, partial molds of each hatchet head were present; these were cast using RTV-112, a silicone rubber molding compound, before the handles were removed.

Stamped inscription preserved on iron hatchet blade.

The mark reads “No. 2/ USSELL & ERW / MANF’G Co. / WARRANTEED”.

By chance, the stamped impression of a maker’s mark was preserved in one of the natural molds of the hatchet heads. The inscription appears to read “No. 2/ USSELL & ERW / MANF’G Co. / WARRANTEED”.

Front cover of the Russell & Erwin

Manufacturing Company’s 1865 catalogue.

Through an educated guess, this mark was identified as the stamp of the Russell and Erwin Manufacturing Company, which manufactured goods in Connecticut and had a warehouse in San Francisco. A reprint of the company’s 1865 catalogue was obtained from the Texas A&M University library. All of the artifacts discovered to date in the crate are listed in this catalogue. As a result of this discovery, the Brother Jonathan crate is currently believed to represent a shipment from the warehouse in San Francisco to a general store in Portland or Victoria.

A pair of cast iron hooks recovered from the crate.

Hooks

To date, eight packages of single cast-iron wall hooks have been removed from the crate. The packages are wrapped in paper and tied with string, and it appears that each has a small rectangle of paper, possibly a product label, at one end. One badly damaged intact package of hooks (BJ-17-42) was X-rayed and carefully unpacked. It contained 72 hooks. Due to the similar sizes of the other packages, it is assumed that they contain the same number of hooks. The Russell and Erwin catalogue lists these hooks for sale by the gross (18 pieces), thus each of the excavated packages holds

Illustration of a hook from the Russell & Erwin catalogue

four smaller parcels containing one gross.

The hooks were put into a sodium sulfite solution, sealed, and placed in a warming oven at 60°C. Hamilton (1996: 80) describes the effects of this treatment as follows: “When a marine iron object is immersed in this hot reducing solution, the iron corrosion compounds are converted to magnetite, and the chlorides are transferred to the solution and discarded with each bath change.” Following two treatments of sodium sulfite, the hooks were thoroughly rinsed, then boiled in deionized water until all chlorides were removed. The next step was to coat the hooks with three layers of tannic acid and coat them in microcrystalline wax.

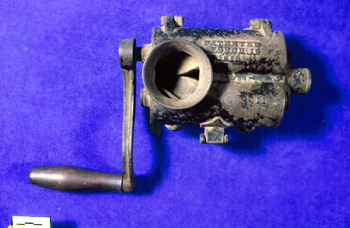

Interior and exterior of meat grinder from the Brother Jonathan crate.

Meat Grinders

Four cast-iron meat grinders were excavated in spring 2001. During fall 2001, surface debris and concretion were removed and all components were disassembled, permitting examination of the interior of the grinders. Most of the metallic iron in the grinders has corroded, leaving only a graphite skeleton of the artifact. Unfortunately, during cleaning, a small piece of the grinder disinteg1rated. Research shows that the missing piece was a blade that ran down the center of the mincer between the rollers.

Through an online auction, Dr. Hamilton purchased a working example of a small grinder similar to those recovered from the crate. This antique will be used for comparative purposes. This grinder has one essential feature that was lost on the Brother Jonathan grinders: it contains the blade in the center of the mincer. By molding this blade, a replica cast will be made for the Brother Jonathan grinders.

All four grinders recovered from the crate exhibit the same cast markings: “PATENTED / MARCH, 15 / 1859.” Research indicates that Albert Hale filed a patent on this date for the Hale Meat Mincer (United States Patent #23,246).

Meat grinder purchased through online auction for comparative research.

The exterior casings of the meat grinders have little remaining iron, while the interior cylinders are better preserved. It should be possible to conserve the rollers using sodium sulfite. As long as the mostly graphitized casing retains some level of magnetism, indicating the presence of metallic iron, the same treatment can be used on these components.

Conservation of two grinders, one large and one small (BJ-17-25 and BJ-17-27), began in February 2002. After three months in three warm baths of sodium sulfite, the pieces were rinsed and placed in deionized water. Upon completion in May, the results were found to be excellent. The treatment removed remaining concretion and only the casing stuffer of the small grinder exhibits a slight degree of degradation. After several boiling baths to remove remaining chlorides, the pieces were painted with three coats of tannic acid. The final step of this process was to coat the pieces in microcrystalline wax. Conservation of the two remaining grinders will begin in fall 2002.

Plumb Bobs

Unwrapping and cleaning a paper-wrapped package of plumb bobs.

Conservation of a package of brass plumb bobs (BJ-17-24) found in spring 2001 required a technique to preserve the paper wrapping while extracting the contents for separate treatment. A new technique developed at Texas A&M University using silicone oil polymers was selected to address these unique problems. The silicone oil will have no ill effect on the brass; and will allow the plumb bobs to be treated using electrolytic reduction.

The intact package was put through a standard series of dehydrations baths used at the Conservation Research Laboratory. The treatment solution consists of silicone oil (SFD1) with 35% methyl trimethoxysilane (MTMS) by volume added as a crosslinker. The package was immersed in the silicone oil solution and placed under a vacuum. After 24 hours, the package was removed from the solution and the excess silicone oil was allowed to drain over a period of several days.

Examples of brass plumb bobs from the crate.

After cleaning and documentation of the entire package, it was slowly and carefully unwrapped. After unwrapping, the brass plumb bobs were removed. The silicone was polymerized in the paper with the addition of a catalyst. The reconstruction of the package is ongoing. Torn pieces will be glued together using butcher paper as a backing instrument. During this process, the shape of the package has been maintained by carved foam replicas of the plumb bobs.

The plumb bobs are brass with steel tips. Due to galvanic action in the saltwater environment, the tips of the plumb bobs were lost. Reproductions of the steel tips will be cast in epoxy resin. The brass component of the plumb bobs are currently undergoing electrolytic reduction. Careful monitoring during summer 2002 will insure that treatment can be completed during fall 2002.

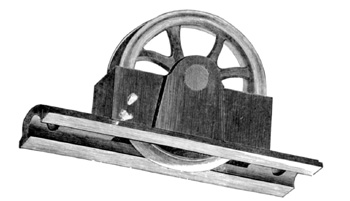

Arrangement of door rails within the crate.

Door Rails

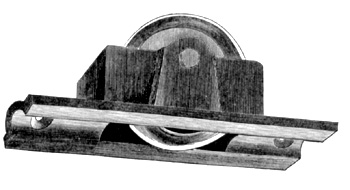

In fall 2001, we removed an array of artifacts from the north side of the crate. The cast iron rails were originally identified as possible guides for sash windows. The 1865 Russell and Erwin manufacturing catalogue indicates that these are sliding door rails of the type used with pocket doors. Large pulleys were used in conjunction with the rails.

The total artifact count for this lot is 50, comprising 25 pairs of rails. Each pair was wrapped at an angle with a single sheet of lightweight paper. The placement of the rails in the crate provides further evidence that the crate is being excavated upside down. During removal, the uppermost pair was always wedged under the next pair. If the crate were to be turned “right side up”, the top pair would be free and not wedged under another.

Large Pulleys

In spring 2001, six packages of cast-iron pulleys with brass pins were excavated. Using X-rays, it was determined that each package contained four pulleys. In October 2002, two of the more degraded packages were unwrapped. Two types of paper were wrapped around the individual pulleys: the exterior of the package consisted of a thick, heavyweight paper, while the inner layer consisted of a lightweight paper. This appears to be true for most paper-wrapped packages in the crate.

Currently one intact pulley package and three individual pulleys are undergoing solvent dehydration. Conservation will follow a method similar to that described for the plumb bobs. Trials to evaluate the effectiveness of the polymer passivation process on badly degraded cast iron objects have begun. If this treatment is not satisfactory, those pulleys with minimal ferrous material remaining will be treated with sodium sulfite. Neither treatment is expected to have any ill effect on the brass pins in the pulleys.

Scythes

Scythes

Two fiber-wrapped packages, each containing six scythes, were stored in a 5% sodium sesquicarbonate solution following excavation in spring 2001. Desalination and dehydration of the packages occurred during the spring of 2002. One of the packages was immersed in a solution of silicone oil with 35% MTMS by volume for approximately one month. Excess silicone oil will be allowed to drain from the package over the summer. The silicone oil will be catalyzed with the addition of DBTDA and the final mechanical cleaning process will begin in fall 2002.

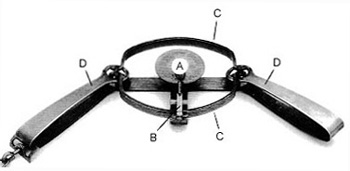

Long Spring Traps

Long Spring Traps

The second layer of the east half of the crate contained many voids left by corroded iron artifacts. Epoxy was used to cast all voids. Lot BJ-17-18 consisted of two obvious shapes: a horizontal, hollow, flat, rectangular piece with holes and a thin V-shaped piece containing some intact metal. Following casting, cleaning, and research, it is believed that these pieces belong to a set of long spring traps. The V-shaped portion (D) of the trap is the spring; each trap has two.

Parts of a long spring trap.

While no intact metal remained in the bases, some metallic iron was preserved in the springs. Because the springs needed to be flexible, they were forged using higher-quality iron than was used for the base pieces. Curved cavities with a central ridge were uncovered along the east edge; these have also been cast in epoxy. These are the jaws of the trap (C). There are no teeth on the jaws, suggesting that the traps were intended for hunting small animals.

Two other artifacts observed in the crate may also be associated with the traps. Iron rings were found in three separate places and small lengths of chain were also found in two separate areas of the crate. Traps of this kind were often strung together in a series using chains and hooked in the center by a ring. Casts of the rings were made using silicone rubber.

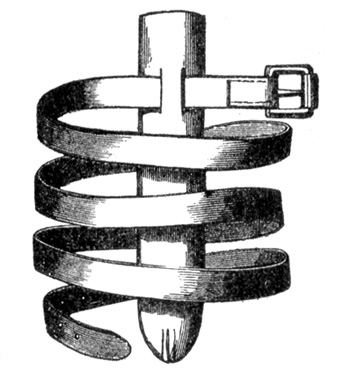

Leather Sheaths

Several leather sheaths were uncovered near the bottom of the crate. At the end of the each strap was an iron buckle and a small leather loop for securing the excess strap. It appears that the cross bar of the buckle may have been covered with a copper tube to protect the contact point with the tongue. The loose ends of the straps are wound together, while the other end is threaded through the upper portion of each sheath. The sheaths will be among the last artifacts removed, as they are intertwined and several are located underneath other artifacts.

Augers

One wooden tool handle (BJ-17-43) shaped like a small rolling pin was discovered in late spring 2001. Removal of the cast iron rails (BJ-17-41) exposed other similar pieces. The metal portion of the tool was cast in epoxy. Instead of the expected spiral auger shape, the tool cavity had a square cross-section with a 30° twist 2 cm below the handle. Four other auger handles were removed, and four more remain in the crate. At least three different sizes of handles can be distinguished. Some of the tools may be bunghole borers, used by coopers in manufacturing casks and barrels.

Wooden tool handle (BJ-17-43), possibly for an auger.

Small Pulleys

Small Pulleys

Two packages of small pulleys (BJ-17-65 and 73) were excavated. X-rays reveal that these pulleys have iron axles, in contrast to the brass pins used in the larger sheaves described above. At least one more package (BJ-17-40) will remain in the crate until fall 2002.

Mortise Latches

Mortise Latches

Two packages of small sash window or shutter locks were excavated in spring 2002. X-rays indicate that the locks are iron, while the faceplates are brass.

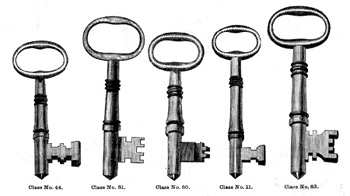

Brass Keys

Brass Keys

One package of brass keys was excavated in spring 2002. The total quantity of keys is currently unknown. However, the catalogue lists keys by the dozen, so a multiple of 12 is expected. The keys will be removed and placed in electrolytic reduction, while the wrapping paper, due to its substantial weight, is suitable for silicone oil conservation. The removal of the keys will begin in fall 2002.

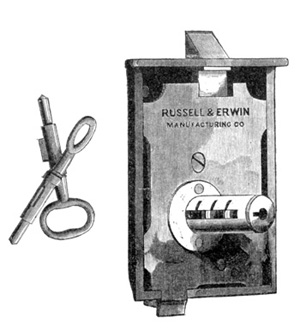

Door Locks

During spring 2001, a package was discovered containing two brass keys and a small brass strip. The interior of the package contained an unidentified mechanical anomaly, tentatively identified as the inner workings of a clock. Following excavation and radiography of the package in spring 2002, six locks have been identified. These are termed “Patent Cylinder Rim Night Latches” in the Russell and Erwin catalogue. The lock works are manufactured primarily of brass, with an iron casing. It will probably be necessary to disassemble the locks in order to treat the brass and iron components separately.

Door Knobs

Two packages of doorknobs were excavated from the lowest level of the crate. These appear to be mineral knobs with brass and iron hardware. While all of the iron components have disintegrated, some molds were made of remaining impressions of the screws. Hopefully, the missing iron pieces can be reconstructed. Conservation of the knobs will begin in fall 2002.

The Crate

The worm-eaten, fragmentary, and heavily encrusted wood forming the crate has been removed from all of the sides except the bottom. Many samples have been collected, including two knots that provide an accurate thickness for the boards. A graduate student in the Nautical Archaeology program at Texas A&M University is analyzing the boards, wood shavings, and the grass packing material. The wood from the box has been identified as Juniperus virginiana, commonly known as Juniper, or Eastern Red Cedar. Over the summer, work will continue on the identification of the grasses. The wood shavings could not be identified because they were cleaved along the grain and no cross sections were preserved.

Back to main page for Brother Jonathan report

Citation Information:

- Carrie E. Sowden, Helen Dewolf, and Donny L. Hamilton

- 2001 The Brother Jonathan Crate: Opening the Crate, Conservation Research Laboratory Research Report 12-1, World Wide Web, URL, https://liberalarts.tamu.edu/nautarch/reportlist/crl-reports-chest-from-the-brother-jonathan-shipwreck/a-chest-from-the-brother-jonathan-shipwreck-part-2/, Nautical Archaeology Program, Texas A&M University.Email: carriees@hotmail.com