CRL Reports: Conservation of an Iron Blade

Composite wood / iron objects: pole arms and partisans

La Salle Shipwreck Project

Texas Historical Commission

CONSERVATION OF AN IRON BLADE

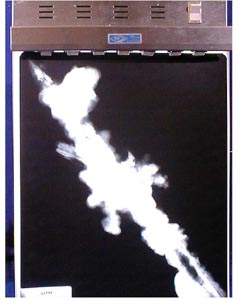

Radiographs (right) of encrusted metal artifacts, such as the partisan (below), can reveal where sound metal remains, as well as show areas of metal that have since corroded. It is sometimes difficult, however, to determine from the X rays if the corrosion products are solid or if they are merely loose slush. To find out, the conservator has no choice but to break open the encrustation. If all that remains is loose slush and a natural mold of the artifact, the mold can be easily cast in epoxy. If the corrosion products are solid, a different tactic must be used.

Radiographs (right) of encrusted metal artifacts, such as the partisan (below), can reveal where sound metal remains, as well as show areas of metal that have since corroded. It is sometimes difficult, however, to determine from the X rays if the corrosion products are solid or if they are merely loose slush. To find out, the conservator has no choice but to break open the encrustation. If all that remains is loose slush and a natural mold of the artifact, the mold can be easily cast in epoxy. If the corrosion products are solid, a different tactic must be used.

When the encrusted partisan (above) was broken in half, we realized that the corrosion products were, in fact, solid. Our original plan of casting the entire piece had to be slightly modified.

After the broken encrustation was fitted back together, it was pressed into a box containing plaster-of-Paris (below left). The plaster supported the back half of the encrusted piece, while the conservator slowly removed the encrusted top half. The conservator used an S.S. White Airbrasie unit to cut through the encrustation (below right). The precision of this tool ensured that the thin cutting edge of the partisan blade would not be inadvertently destroyed.

Conservator using an W.W. White Airbrasie unit to cut through the encrustation

Broken encrustation fitted back together, sitting in the box of plaster of paris

After cutting off the top surface of the encrustation, all of the metal corrosion layers were removed. Special care was taken to clean the sharp edges of the blade. Hysol LE-6329 NA epoxy (no longer available) was poured into the open areas, making sure it flowed along the edges. The different pieces of the top encrustation were then placed on top of the epoxy, so that it would pick up the natural surface of the original blade surface.

Silicone rubber mold made of part metal/part epoxy partisan

Part epoxy/part metal partisan removed from the encrustation

Part metal/metal oxide and part expoxy partisan as removed from the encrustation after filling voids with epoxy

Silicone rubber mold cast with Hysol LE 6329 NA epoxy

Cast after coating with graphite to give it a metallic appearance

After the epoxy set, the cast was removed and covered with a coating of graphite to give it a metallic appearance (right). There is additional work to be done on the metal straps that project from the partisan, connecting it to the shaft.