HMS Victory (1765) Capstan

Modeling Shipboard Equipment

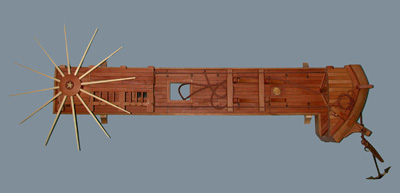

A capstan based on HMS Victory’s

Glenn Grieco recently completed construction of a fully functional capstan. The model is often used in a class about the outfitting and sailing of wooden sailing ships, taught every second year by Dr. Kevin Crisman. The model is based on the main capstan of HMS Victory, although with a greatly shortened deck. Construction of Victory, Lord Nelson’s flagship at the Battle of Trafalgar, began in 1759. She is the oldest warship of the Royal Navy still in existence.

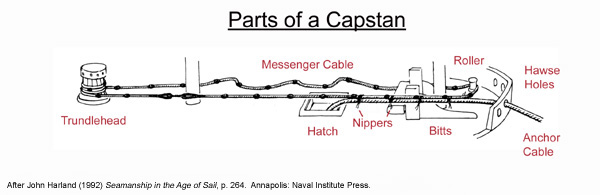

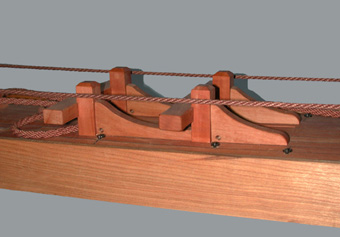

The main capstan was used to weigh the anchors. As ships grew larger, so did their anchor cables, until during the 17th century they became too large and heavy to wind around the capstan. Instead, a messenger cable was wound around the trundlehead and around rollers, forming a continuous loop. The anchor cable was temporarily secured to the messenger using small lines known as “nippers”. The nippers were then handed to boys who walked aft along the deck, trying to keep the heavy, wet cable and messenger from dragging. The nippers were removed when they reached the main hatch to allow the cable to be fed down into the hold, where another large group of sailors stowed it neatly.

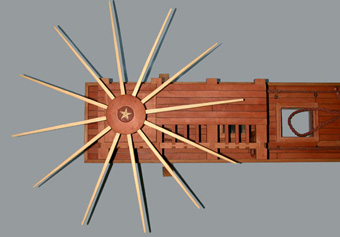

Up to 14 capstan bars could be fitted into the sockets around the drumhead on the middle gun deck, and 12 bars could be used with the trundlehead on the lower gun deck. The model uses slightly fewer bars than the original ship. Ten men could be stationed at each bar, and 260 people were sometimes needed to haul in the anchor and cables. Up to 10 tons could be lifted using this arrangement; a cable of 120 fathoms weighs seven tons. The entire process could take between 30 minutes and six hours, depending on the length of cable used.

|

|

|

rollers and cable entering through hawse hole. Normally, there were four hawse holes |

|

|

|

|

|

|

|